Why Japanese Furniture Is Built to Last — A Factory Tour in Okawa, Japan

Share

The other day, I visited two furniture factories near Okawa City, Fukuoka, together with Sekai e Bokkan (a cross-border eCommerce partner).

Okawa is often called a “city of furniture,” but every time I visit factories, I’m reminded of one thing:

Even in the same Okawa area, each factory has completely different standards for craftsmanship.

This time was no exception. At each place, I found myself thinking, “Ah—this is how they build furniture, and this is what they care about.”

First stop: Wako Co., Ltd. — a workshop centered on kiri (paulownia) tansu chests

Furniture stability is decided by wood selection—before craftsmanship even begins

The first topic was how Wako selects lumber. When we talk about furniture, we often focus on design, finishing, or price, but what struck me most was this idea:

The quality of furniture is largely determined by which wood you choose.

In practice, Wako’s perspective can be summarized like this:

- Use lumber with high density and stable quality.

- Avoid wood that may warp or “move” later—even if it looks visually dramatic.

- Even for kiri (paulownia), prioritize material quality over price or lightness.

None of this sounds flashy, but if you truly want furniture built for long-term use, it felt completely reasonable.

Itame vs. Masame (Kime): “beautiful grain” and “stable wood” are not the same thing

The explanation about grain patterns was especially memorable. In Japanese woodworking, you often hear about Itame (板目) and Masame (柾目).

Itame (板目) — characteristics

- Bold, dynamic grain that looks very attractive.

- Because of how it’s cut, the grain tends to run more horizontally.

- As a result, it can be more prone to twisting or movement over time.

Masame (柾目) — characteristics

- Cut in a way that produces straighter, more consistent grain.

- Less likely to move or warp, making it easier to control for long-term stability.

- Well-suited for furniture intended for long-term use.

At Wako, the decision is clear: they mainly use Masame (柾目) for production.

Of course, skilled traditional craftspeople may be able to correct twisting in Itame pieces later— but Wako’s approach is more fundamental:

Choose wood that is less likely to move in the first place.

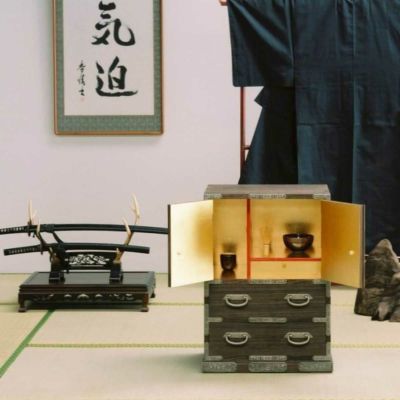

Bringing Japanese culture “inside the storage” — the BOTAN kiri display tansu

One of the most personally impactful pieces was a culture-inspired storage box called BOTAN.

To be honest, it’s not designed for mass production, and it’s not an easy piece to build. But as we talked, I started to understand why this form matters.

- An interior appearance that evokes historical Japan.

- A traditional structure using “neck and leg” elements.

- Bamboo—an iconic symbol of Japanese culture.

- A goza (woven mat) placed inside the drawers.

What surprised me: the goza inside has been there for over 8 years, and it still retains its scent and color well.

By controlling UV exposure and maintaining breathability, the design avoids “over-sealing” the contents. It felt like wisdom shaped by Japan’s humid climate—built into furniture.

Not “hiding,” but “not being noticed” — a uniquely Japanese approach to security

Another memorable detail was a hidden structure on the underside of a drawer—hard to notice even when looking closely.

This isn’t just about theft prevention. It reflects a very Japanese mindset:

Security that doesn’t assume the other person will understand what they’re seeing.

The story reminded me how traditional Japanese ideas for protecting valuables can still live inside modern furniture design today.

Second stop: R-Tech Co., Ltd. — solid wood tables at the center of production

We filmed an interview inside the workshop. The sound of production was loud, so I personally couldn’t catch every detail— but I expect our cross-border eCommerce partner will publish the interview later.

Even in Okawa, standards differ dramatically from one maker to another

What I felt again this time was simple:

The term “Okawa furniture” alone doesn’t tell you anything.

Wako has clear standards for lumber selection, a clear reason for using Masame (柾目), and a philosophy of embedding cultural meaning into structure. That doesn’t automatically apply to every factory in Okawa.

That’s why I think the key is this:

Which maker builds it—and by what standards?

By the time we left the factories, I felt I could finally put into words—at least a little—why people overseas choose Japanese furniture.

Not flashiness. Not efficiency. But standards, accumulated over time. The craftsmanship we saw at these two makers felt like the perfect example of that.

After the tours, the sun had already set.

And to wrap up the day, we held a small “decision rally” of our own—to spread the quality of Okawa furniture overseas even more.